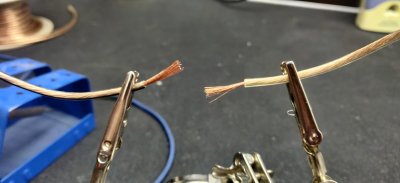

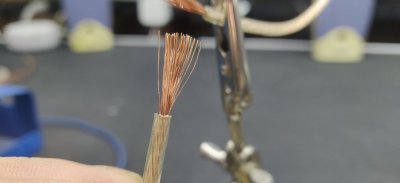

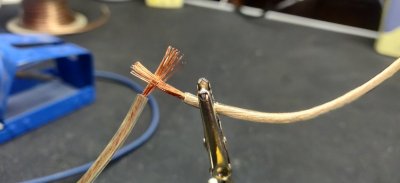

with a lot more people working on their trucks and adding lights, relays, switches, etc i figured i should post how i think is the proper way to make a connection. there are a few different ways to make an electrical connection and i will go over some of them. first up is soldering. now this is a controversal type of connection because its very easy to improperly solder wires together. this first pic is how i see many people solder. they tin both sides of the wires and then melt the solder between the two wires while the wires are touching. i purposely half assed the job because this is a typical type of solder connection i see when this is done this way. as seen in pic #2. a lot of times people will try to solder and since they are connected, think it will hold. however just having the solder as the "mortar" holding these two wires together, is not a solid connection and the solder can break causing the wires to seperate.