TravisHTX

Full Access Member

i guess the complete assembly could/can be called a solonoid..

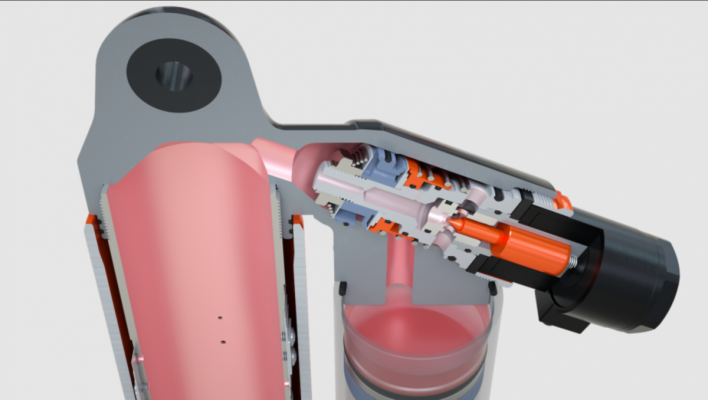

the coil is a magnet, and the part that screws into the shock is a needle valve, that yes controls the flow of oil into the shock reservoir internal piston area..

but basically, its a needle valve array for controlling oil flow, outside of the piston/shim stack mounted to the main shock shaft..

all its really doing is turning the manual knob that is on the older shocks, until you talk about gen3 that is adjusting the knobs constantly..

maybe something in the live valve is failing and making them full stiff after time... thatd be pretty lame.

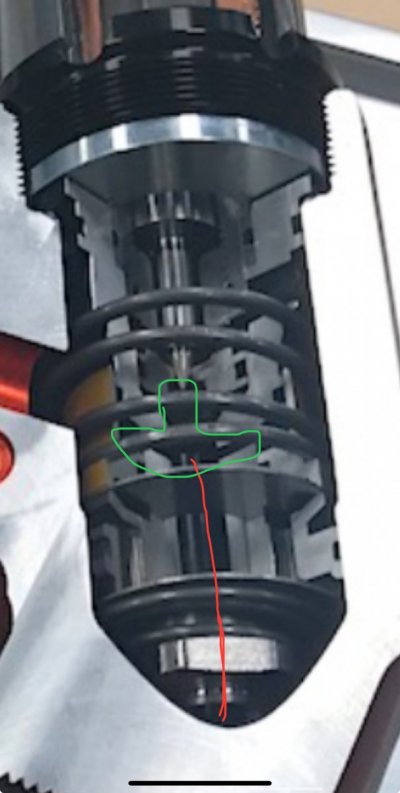

if the needle isnt pulled back, they are full stiff..

so id bet its possible that the needle is getting stuck in its seat and the magnet cant pull it back...

I understand your point. And yes, that has been one of my questions, how likely is it that the valve just gets jammed in the closed position. Maybe that possibility is so slim it’s not worth considering.

The “emulsification” of the oil does certainly makes a lot of sense.

I am thinking of getting a new set of shocks so I have limited down time.

I have no problem cracking one of the old ones open, I just don’t know how helpful it would be since I have no experience doing that before. We need a pro to give us a demo of what one of these look like old vs new!