So, I decided to upgrade the TWINS. And since I am no longer restricted by my warranty, I am removing the factory restrictions from the intake and exhaust in one fell swoop. I am calling this project “No Restrictions".

I’ve done a lot of things with engines. This was my first turbo swap. I wasn’t able to find much information on the Garrett Power Max stock location turbos in this forum (or in general online), so I thought I would share more of my experience for those whom may be considering similar modifications. I have a 2017 Gen2 that has 73k on the clock. I have no warranty left and these parts look gorgeous. She is still young enough to have some fun. I have read a lot about different performance modifications and it’s now time to play. I assume a few others are nearing my situation with their Raptor and considering doing all the things you thought you would lose your warranty over. Here is my write up on a turbo swap for the Gen2 Raptor including part numbers, some great tools, and a few lessons learned. I hope to use this myself for future reference, and certainly hope that it may help others understand the process steps. Sometimes it’s just nice to see what these parts look like.

I took notes during my recent install. Some of this is repeated elsewhere. My apologies for the duplication, but I am attempting to be comprehensive in one post such that this can be used to reference the whole job.

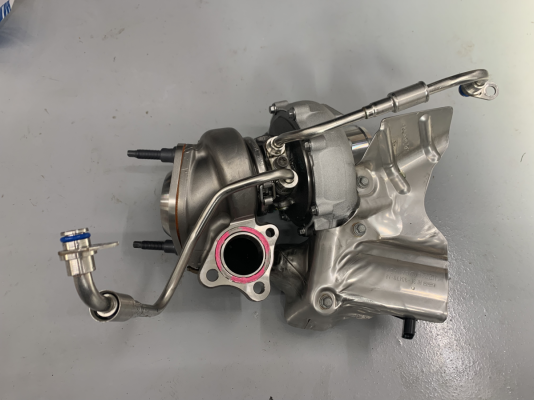

First thing…. You WANT these. These turbos are just gorgeous. The first thing to point out is that these are electronically controlled wastegates, just like the stock parts. Many may not realize this, but these are super fancy parts. I’d recommend staying away from vacuum actuated turbo wastegates that are available out there. You know how it feels when parts turn up looking better than expected? I do now! These things give me serious wood. Really nicely made. I took photos like these turbos were my newborn children. Are these emissions compliant? I don’t know. My modifications retained the stock downpipe, exhaust, and all catalytic converters so there is a reasonable chance it would still be compliant with an emissions test. Michigan for better or worse does not conduct an annual emissions audit, so I am unable to confirm compliance.

When considering doing this job, I knew it would be a fair amount of effort. I purchased the service manual to read up on what I was getting myself into. I felt prepared, but we always seem to forget a few odds and ends. Can you do a turbo swap yourself? Sure! But possibly not over a single weekend. I spent a few days waiting for parts and a few more days waiting for tools. Then a few more days waiting for parts. Ha! Those unfamiliar with service manuals may be surprised with a few maintenance items buried in the overall service. These necessitated new seals for the most part. No biggie, but hopefully this information will help you guys spend less time driving to the dealership.

So, how hard is it? Well, she really isn’t as easy to work on as those old muscle cars. Most of the time spent doing this job is removing and replacing things in the way of what you want to work on. To do this job, you will be draining the coolant, pulling all intake tubes, removing the grille, radiator, the intake manifold, the starter, unbolting the AC compressor, as well as removing all of the skid plates, fender flares, front wheels, and their liners. You will disconnect the PCV tubing as well as the brake booster (That's what all those tubes are on the right of the engine bay!). All of this is removed to provide access to the turbos - which you access through the wheel wells with the tires off. Clearly, a lift or jack stands are required. It’s tight but it’s manageable. Take your time.

I spent two weeks doing the mechanical portion of this job, working on it a few hours a day and spending a lot of time waiting for things. If I planned better, I assume I could knock this out in about 3-4 days. I am not a professional mechanic. White collar here with a love of tools and a few bloody knuckles. I would plan a full day for disassembly, a full day for reassembly, and 1-2 days for swapping out parts and dealing with those pesky lines. A helper would be nice, but not required. The real time input seems to be tuning. I spent roughly 3 weeks going back and forth with a tuner to get everything dialed in. While you could pull off the mechanical portion of this job over a long weekend, you may want to plan adequate time to complete the tuning process.

I consider myself a good wrench, even though I have not needed to work on my daily driver in almost 2 decades. After taking on this project, I was surprised at how many things have changed. As a quick example, I was all ready to wrestle open the lower radiator hose to drain the coolant for a flush and fill. I mistakenly thought I could just fill up the reservoir tank to refill. I guess this is showing my age! Ford pleasantly includes a drain valve on the radiator itself. There is even a nipple to attach a 3/8 hose so that you don’t make a mess. If that is not fast enough for you, there is a quick disconnect on the lower radiator hose. The manual requires a vacuum purge and fill of the coolant. This actually makes a lot of sense for keeping out trapped air. Let’s get the new tool on order

Before you start taking your truck apart….

Buy the service manual, then read it including the subchapters. I found my service manual to be fairly complete. The pictures were great. Torque specs appreciated. It did not include part numbers, but the local Ford dealership was great help with that and I included the numbers below for easy reference. The most I had to wait was about 2 days for an OEM part to come in. No, unfortunately Ford doesn’t yet ship to your house. I got my manual here; https://www.factory-manuals.com/expand-2017-ford-f150-repair-manual-1924.html

What fuel do you have in your tank? How many gallons? If you are like me, you have half a tank of 93 sitting in the garage. I had to drain the tank and refill with 91 in order to start tuning. That sounds simple…. But is sort of a pain in the ***. Can you siphon the tank? Maybe. The cap-less design does make that a little more challenging. Do you have enough containers for roughly 30 gallons of fuel? Even temporary storage can be challenging.

Check what grade of fuel is available near you. This may sound stupid. I expected 91 to be everywhere. Nope. Not at the three locations closest to my house. I was able to find 91 at Sunoco which has sparse coverage up here in Michigan. Whatever fuel you are starting with for tuning - It would be easiest if that were already in the tank when you complete the turbo installation. Proper planning here can save a fair amount of hassle. You will need to empty the tank between fuel types. Make sure you have adequate storage available. If you are swapping injectors or fitting the HPFP you will need to depressurize the fuel system anyway. So, this seems to be a good time to drain the fuel off and swap in those fuel system components. Make sure you depressurize before you start disassembly or drain coolant as you need to run the engine for a brief period of time.

You will at minimum need to drain and refill the coolant. I chose to change to a colder thermostat at the same time. The thermostat requires a new gasket seal. It also requires collaboration with a tuner. There are electric fans that work in concert with the mechanical thermostat. If you don’t change the temperature that the fans come on, they will only cool at the factory temperature setting negating the thermostat change. Pick up enough coolant (around 4 gallons) to refill. This truck requires a vacuum purge and fill. Do you have orange coolant? If so, you may need to switch color and do a full flush. Different colors are not compatible.

Why did I do this?

Well, this just seemed like a good bit of fun. Don’t get wrong. These trucks are real performers. I’m smitten. But, there were a few parts I did not like when I took her apart.

Ford does a great job hiding the intake restrictions in packaging. Take a look at the driver side turbo inlet. This was the most offensive part under the hood in my opinion. The Ford engineers give you a decent air filter and voluminous 2.5” intake tubes as far as the eye can see. As soon as they tuck down out of sight, these inlets shrivel down to 1.75” as they enter the stock turbos. OK, OK…. It’s a gradual taper (on the passenger side) down to 1.75” and one could argue that this may still allow for high velocity flow. Explain the tight elbow at the turbo inlet on the driver side. No bueno.

Most any pump is not a “fan" of intake restriction. They all build pressure and can push, but few like to pull air into them. Turbos aren’t terribly different. The inlet tubes are the most apparent restriction under the hood. So, I purchased a set of AMS inlet tubes that provide a full 2.75” all the way down to the turbo. These mate up perfectly to the Garretts. A pair of 45 degree silicone intake elbows and we now have eliminated our intake restrictions. It’s kind of pretty. Packaging is a bit tight. You actually want the plastic tubes and not metal here. Metal allows for too much heat transfer to the intake air in most cases. The plastic are actually quite nice and will protect those air charge temps that we invest so heavily in (intercooler). Fitting the charge tubes in general is a bit fussy. I combined the AMS inlet tubes with the COBB cold air intake. I really like the two completely separate air intake tubes coming from the filter housing. Their filter is a nice reusable filter. I now have a full 2.75” inlet tube from filter to turbo on each side. That will flow more air than this thing can digest. Restriction eliminated.

Possibly more surprising is what I see as a significant exhaust restriction in the stock turbo downpipe adapter. This is only apparent after you take it apart. Regardless of turbo size, this downpipe adapter seems to have been designed to guarantee a nice exhaust seal. Maybe it does that well. What I see is at minimum a 0.250” (that’s a quarter of an inch) lip all the way around where the flange protrudes into what should be exhaust gas flow. Over half an inch in diameter. There is no port matching. Just an abrupt shoulder on the stock parts. One could argue that hot exhaust gases are less dense than incoming air and flow through these ports without too much difficulty. I don’t like how these look. My eye can’t do CFD but I have always had great luck with port matching in the past. A 1/4” step has never been good design practice for flow in my experience. This almost looks like a restrictor plate. ID measures at 2.060” here on the stock adapter.