goalieThreeOne

Member

I'm in the early stages of installing a new audio package for my Gen 3. Part of that package is a full length behind-the-seat subwoofer enclosure for two 10" woofers. I'll detail that in future posts. But that enclosure requires me to remove the factory jack mount behind the rear passenger side seat. What I didn't want to do was stuff in in the under seat tray and take up storage room that I need to store my PPE, FAK, Straps, etc. Plus I didn't want it rattling around. I had considered the swing case, but was unsure if the jack would even fit, plus it blocks the bed light. I did not want to invest in a Hi-Lift jack and none of the bottle jacks on the market had enough stroke for a flat tire with a 9inch sidewall. So figured I'd take a stab at my own solution while re-using the factory jack.

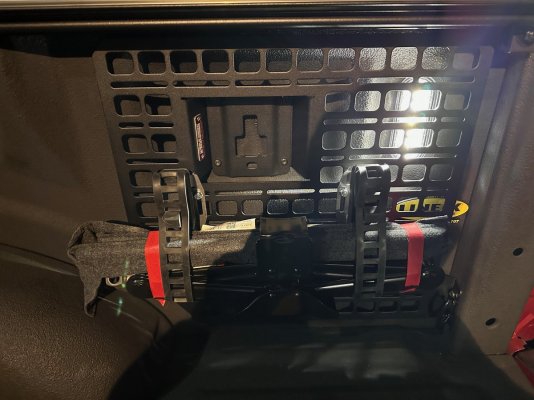

For this project, I started with a BuiltRight Industries Passenger Rear Molle Panel. To attach the jack, I used their QuickFist Long Arm Riser Mount. I also bought a set of their MOLLE hardware, but did not end up using that for this project. After some careful placement, I came up with this:

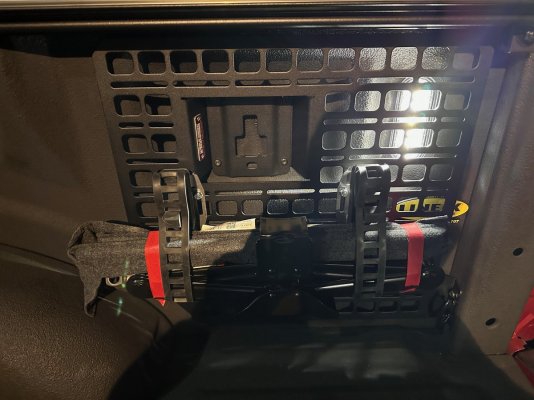

Now this is really nothing new, since the Long Arm clamps are meant for Hi-Lift jacks. But they also work well for the factory jack package. If I decide to invest in a Hi-Lift down the road, it's as simple as adding a small Molle panel to the front BoxLink mount and clamping it across the two panels. The second half of this project will be to establish a way to mount the factory jack extension in a way that doesn't require tools. Right now I'm thinking I'll use the extra MOLLE hardware I got, along with a long 1/4-20 thumb screw and mount it to the MOLLE panel exactly like how it mounts to the factory jack location. I will also try to find a waterproof nylon bag or pouch to put the jack in to protect it from the water that leaks past my Revolver tonneau cover.

The panel does block some light, but it's still far better than a Swing Case. I might end up mounting a light with a flexible arm to this panel, or one on the driver side plugged into the 12V jack, so I can have some light I can position around the bed and tailgate for range trips.

For this project, I started with a BuiltRight Industries Passenger Rear Molle Panel. To attach the jack, I used their QuickFist Long Arm Riser Mount. I also bought a set of their MOLLE hardware, but did not end up using that for this project. After some careful placement, I came up with this:

Now this is really nothing new, since the Long Arm clamps are meant for Hi-Lift jacks. But they also work well for the factory jack package. If I decide to invest in a Hi-Lift down the road, it's as simple as adding a small Molle panel to the front BoxLink mount and clamping it across the two panels. The second half of this project will be to establish a way to mount the factory jack extension in a way that doesn't require tools. Right now I'm thinking I'll use the extra MOLLE hardware I got, along with a long 1/4-20 thumb screw and mount it to the MOLLE panel exactly like how it mounts to the factory jack location. I will also try to find a waterproof nylon bag or pouch to put the jack in to protect it from the water that leaks past my Revolver tonneau cover.

The panel does block some light, but it's still far better than a Swing Case. I might end up mounting a light with a flexible arm to this panel, or one on the driver side plugged into the 12V jack, so I can have some light I can position around the bed and tailgate for range trips.