ZaneMasterX

FRF Addict

Where did you get the HD d-rings?

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Do you have a pic of what you did for the USBs on the radio mount?

Where did you get the HD d-rings?

I recycled the stock USB connector and housing that is in the phone charger tray. That may only be on the 800A package. I think higher models have inductive chargers. Blue Sea has lots of nice marine grade USB outlets that you can use.

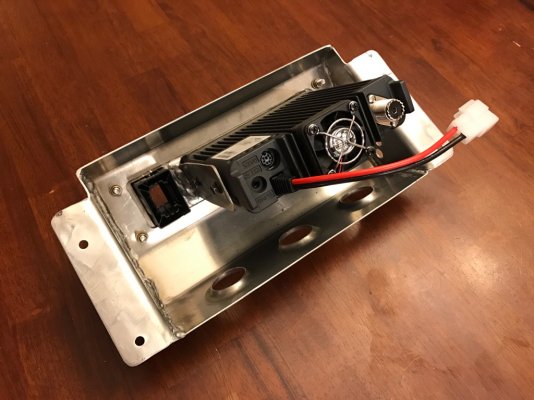

Pic of the stock USB housing from the back

Front

Sent from my iPad using Tapatalk Pro

---------- Post added at 07:59 PM ---------- Previous post was at 07:57 PM ----------

Recycled them from the stock ones. Death wheel and a hammer will have them off in a few minutes. Rewelded on the new receiver tube D ring mounts just above the receiver.

Sent from my iPad using Tapatalk Pro

I finally got the wiring done for the winch, painted the front skidplate and silver part of the bumper and tested out the winch wire connections. Headache rack and bed rails are planned for tomorrow.

All stealth wiring because I don't use the winch that often. Stays under the hood until I need it.

What kind of hardware did you use when you installed those Scepter gas can brackets, etc., in the back of your aluminum bed? Did you follow Ford's guidelines for hardware usage with the aluminum box?

What kind of hardware did you use when you installed those Scepter gas can brackets, etc., in the back of your aluminum bed? Did you follow Ford's guidelines for hardware usage with the aluminum box?