RyanFelish

Member

- Joined

- Aug 21, 2016

- Posts

- 18

- Reaction score

- 25

Steering rack more sloppy than your last girlfriend?

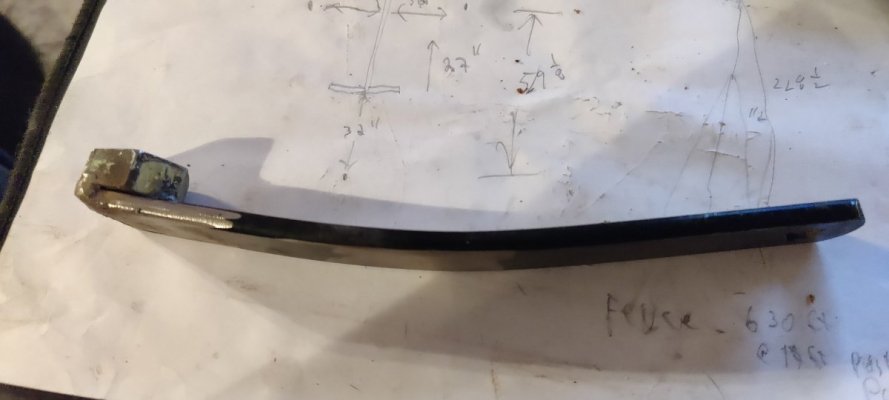

Finally, some answers on steering rack failure, and a video on how to adjust excess steering play! Those that follow my Instagram know that I have been looking at blown racks and working with a hydraulics specialist to see what causes failure, and trying to locate a rebuild kit with better seals for half the price of what Ford charges.

2 Main causes of failure appear to be an out of adjustment rack, and heat.

Solutions, Steering cooler (no new news here!) and adjust your rack when it starts to develop play.

I am still working on some better seals to rebuild the box with, that could take some time. But for now, here's how to adjust your F150 or Raptor steering rack!

If you plan on doing this to your truck, please watch the video fully before starting. Be sure you have a good grasp of what you are doing. Over tightening the rack could potentially cause failure more than your loose one!

https://youtu.be/8X9xpioehv4

Finally, some answers on steering rack failure, and a video on how to adjust excess steering play! Those that follow my Instagram know that I have been looking at blown racks and working with a hydraulics specialist to see what causes failure, and trying to locate a rebuild kit with better seals for half the price of what Ford charges.

2 Main causes of failure appear to be an out of adjustment rack, and heat.

Solutions, Steering cooler (no new news here!) and adjust your rack when it starts to develop play.

I am still working on some better seals to rebuild the box with, that could take some time. But for now, here's how to adjust your F150 or Raptor steering rack!

If you plan on doing this to your truck, please watch the video fully before starting. Be sure you have a good grasp of what you are doing. Over tightening the rack could potentially cause failure more than your loose one!

https://youtu.be/8X9xpioehv4