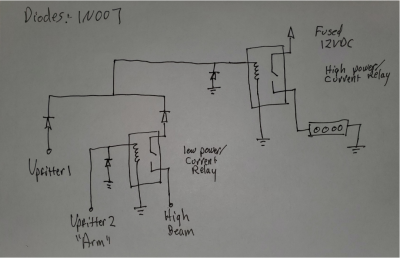

Ok, now I know what you are asking. The answer is you need diodes for both of the cases I originally described. You can use the same readily available 1N007 diode for all three diodes below.

You're getting lots of different advice including that diodes aren't needed at all. That may be right, but since you don't know what is driving the two input signals below (upfitter switch and high beam) the right way to combine the outputs of two different power sources is shown below. Normally those would be Schottky diodes (different part number) but for your application 1N007 will be fine. These are different power sources because they won't have the exact same voltage (two different paths from the battery) and the high beam especially may be driven by a solid state device which induces its own voltage drop relative to the 12 VDC source. Never connect two power supplies (or signals) directly together unless you know the drivers of those power supplies (or signals) are designed to support that. We don't know in this case.

The two lower diodes prevent one input from driving back to the other input's driver which is very important if the other input is a solid state device. If both inputs are driven by mechanical relays then this would be less important to do, but the conservative design approach is to assume the worst case.

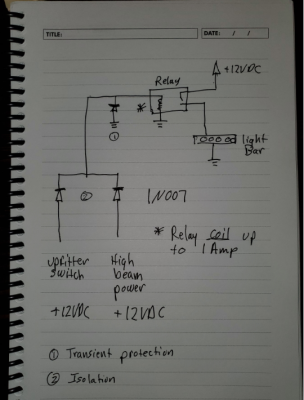

The top diode is used to protect the rest of the circuit from the transient voltage that is induced when the relay is turned off. Some automotive relays have these built in. Since you don't know, use the conservative approach. These diodes probably cost less than 20 cents each in small quantities so adding them is no big deal.

This diode selection is fine as long as the steady state COIL current of the automotive relay in the picture does not exceed 1 A. Most are well under 0.5 A.

Use at your own risk. This is not offered as professional engineering advice.

View attachment 160670