bubblehead93

Full Access Member

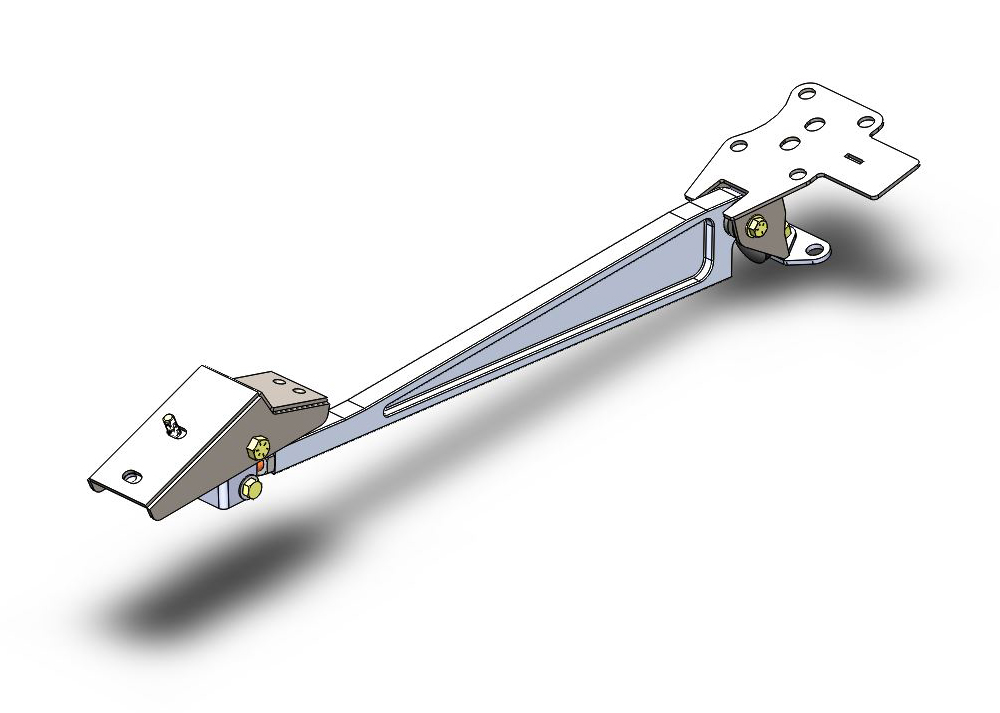

no axle wrap! its awesome, that windup and release feeling at WOT shifts is gone...

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

That wind up and release....great wat to put it.... reminds of those old pull back toy cars I hadno axle wrap! its awesome, that windup and release feeling at WOT shifts is gone...