frogslinger

Full Access Member

- Joined

- Mar 23, 2010

- Posts

- 1,072

- Reaction score

- 4

So to straighten me out the part problem was those three missing pressure indentations?

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

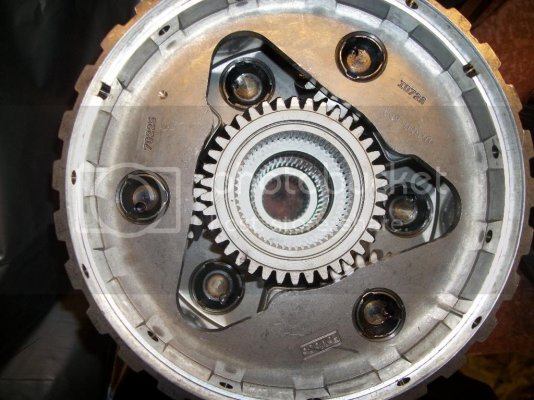

Kaiser, all six pinion shafts were missed.FSM, judging from the pic, there are at least two loose pinion shafts. How many unpeened shafts were in this carrier? Thanks for sharing all of this. Very interesting.

This is captivating FSM06. I have a couple of questions if you got time.

1. Why is there so much metal on the new gear tooth faces?

View attachment 186View attachment 188

Is this normal on new gears? I would think that is excessive flashing/tooth cutting residue. Must be a hell of a filter... or the magnet always has it's chia pet look!

What did this grind on? Did you have to replace that part too?

View attachment 189View attachment 185

View attachment 190

What is that small hole? Balance mark? That is a one piece shaft, right?

Thanks for all the cool pictures. I just thought the volkswagon tranny I tore down was complicated <G>.

Falcon