Dan06

FRF Addict

Haven't started a new thread in awhile. So I have an idea, get good ones from time to time. Occasionally a few come to fruition...

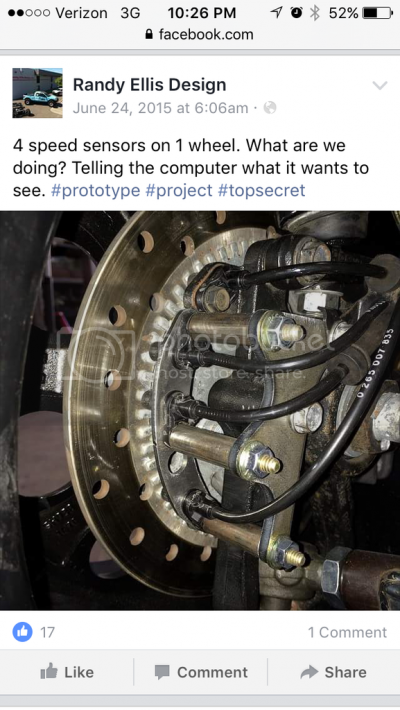

Ok we know our IWEs are crap, that's a given. A fabricated spindle has been mentioned in the past as a way to integrate another option such as a locking hub. However the tone rings and wheel speed sensors would pose the main complications.

Here's my idea:

Tie the front wheel speed sensors into the rear. I've actually seen all wheel speed sensors on one tone ring before.

Disable traction control and ABS, which would be the next major roadblock.

Then Aftermarket HQ has developed a BRTS ELD Controller to lock the rear dif.

At which point the fabricated spindle would be the easy part.

Any suggestions or comments? See any issues with the idea?

Ok we know our IWEs are crap, that's a given. A fabricated spindle has been mentioned in the past as a way to integrate another option such as a locking hub. However the tone rings and wheel speed sensors would pose the main complications.

Here's my idea:

Tie the front wheel speed sensors into the rear. I've actually seen all wheel speed sensors on one tone ring before.

Disable traction control and ABS, which would be the next major roadblock.

Then Aftermarket HQ has developed a BRTS ELD Controller to lock the rear dif.

At which point the fabricated spindle would be the easy part.

Any suggestions or comments? See any issues with the idea?

Last edited: