You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GEN 2 VHF radio mounting (looks factory!)

- Thread starter johndjmix

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

WhatExit?

FRF Addict

I'm interested in this as well. Also would be interested in an option for a CB radio and CB antenna so I could switch them out.

And while you're at it, one for a Short Wave Radio and antenna too.

Can never have too many radios off road

And while you're at it, one for a Short Wave Radio and antenna too.

Can never have too many radios off road

dirtslinger

Active Member

Hey John,

I am a desert guy (Class 11 dork) I have the TK-790 so this is perfect for me.

Please keep me posted if you make anymore of these. I'd love to get my head unit out of the my center console so I could adjust volume or squelch without opening my center console.

I am a desert guy (Class 11 dork) I have the TK-790 so this is perfect for me.

Please keep me posted if you make anymore of these. I'd love to get my head unit out of the my center console so I could adjust volume or squelch without opening my center console.

I'm going to attempt to make a few more of the panels while I have the antenna mounts in testing.

The issue is, right now, between cnc time, sanding/grinding, and welding the tabs, carbon fiber wrap, And the fact that it takes me around an hour to make each one I'd have to charge around $150 each. Let me work on getting our production shop on it so I can get the price down.

Sent from my iPhone using Tapatalk

The issue is, right now, between cnc time, sanding/grinding, and welding the tabs, carbon fiber wrap, And the fact that it takes me around an hour to make each one I'd have to charge around $150 each. Let me work on getting our production shop on it so I can get the price down.

Sent from my iPhone using Tapatalk

Maybe consider just doing the cutting and letting people finish their own. There's probably a lot of people like me who just don't have access to the right tools or they'd tackle these things themselves.

By the way, how much room is under the cubby if you wanted to cut out the bottom for a radio? The ultimate solution for me would actually have the radio inside the cubby so I could hide it when not in use.

By the way, how much room is under the cubby if you wanted to cut out the bottom for a radio? The ultimate solution for me would actually have the radio inside the cubby so I could hide it when not in use.

Last edited:

WhatExit?

FRF Addict

I'm going to attempt to make a few more of the panels while I have the antenna mounts in testing.

The issue is, right now, between cnc time, sanding/grinding, and welding the tabs, carbon fiber wrap, And the fact that it takes me around an hour to make each one I'd have to charge around $150 each. Let me work on getting our production shop on it so I can get the price down.

Sent from my iPhone using Tapatalk

Quality products especially specialty products like this customized for a Gen2 Raptor, aren't cheap. Make a high quality product people want and they'll buy it!

Can't wait to see what you come up with

marcomilano77

Full Access Member

- Joined

- Mar 26, 2016

- Posts

- 155

- Reaction score

- 119

Maybe consider just doing the cutting and letting people finish their own. There's probably a lot of people like me who just don't have access to the right tools or they'd tackle these things themselves.

By the way, how much room is under the cubby if you wanted to cut out the bottom for a radio? The ultimate solution for me would actually have the radio inside the cubby so I could hide it when not in use.

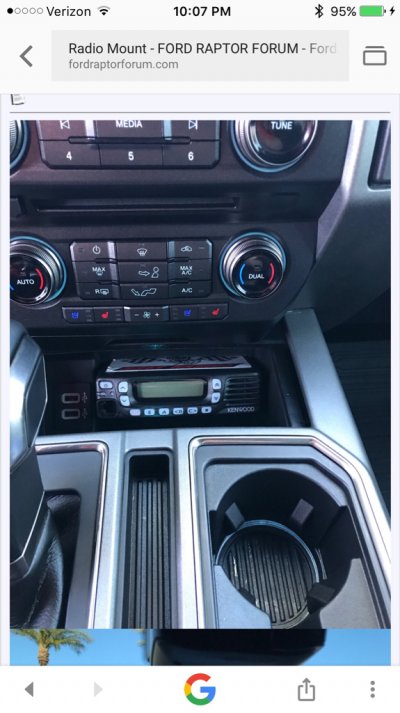

Like this?

Sent from my iPhone using Tapatalk

That small kenwood in there, so you can still close the door looks pretty cool, but personally i prefer the flush mounted look.

Its an EXTREMELY tight fit with the USB and TK-790 head...it hits the sides of the internal bucket. No way to get it below the door level.

Its an EXTREMELY tight fit with the USB and TK-790 head...it hits the sides of the internal bucket. No way to get it below the door level.

I have both prototypes of our manual antenna mount and motorized versions done. The seal they make is better than anything out there. They also use additional fasteners so it's not just the brake light screws holding it on. We are using a very expensive foam sealing material.

I have the motorized version mounted to my 2018, I'd like to send someone the first pre-production version of the non motorized mount free, as long as they give me their feedback.

Anyone interested? Here's a picture of it before powder coat (it's now powder coated black). The production version will be identical except the squared off part in the back will be rounded. First one that PM's me, I'll get you the mount free to test.

Sent from my iPhone using Tapatalk

I have the motorized version mounted to my 2018, I'd like to send someone the first pre-production version of the non motorized mount free, as long as they give me their feedback.

Anyone interested? Here's a picture of it before powder coat (it's now powder coated black). The production version will be identical except the squared off part in the back will be rounded. First one that PM's me, I'll get you the mount free to test.

Sent from my iPhone using Tapatalk

Similar threads

- Replies

- 2

- Views

- 237

- Replies

- 5

- Views

- 3K

Members online

- Tbogo

- Latchkey Kid

- KingKoopa17

- RaptorFun

- sfckelley

- Decoyman

- Patrickcrocetta

- Skai

- BBR

- wac45

- dj30417

- FRAPCNO

- bennyg

- MrMicky

- never_summer

- Suren27

- Morgan

- sc85fiero

- Gumby

- ChevyLee

- MDJAK

- Louisiana Barefoot

- Arctic

- RaptorMach3p5

- TheGrizz

- GCATX

- PK37

- Ol_Blue

- Bsbbrian4

- John813

- ToadSmasher2K1

- Slobojin

- JMH2019FPB

- Swaddict

- pavendort

- sukid

- madenis

- SlickTrick

- nltruck

- K1LDZR2

- nd3

- Old-Raptor-guy

- FGHT ON

- WH7

- Shane361

- poofyo101

- soudaldayoli

- FordPerf Addict

- soccerUber

- WC114

Total: 1,209 (members: 61, guests: 1,148)