Um, not sure if you realize this, but driveshaft rotational speed is determined by the rear-axle ratio. Engine speed has NOTHING to do with it. In this case, the rear end of the Raptor has a same 4:10 ratio as before, so driveshaft RPM remains unchanged.

I'd ALSO add that the EcoBoost doesn't rev very high. Chances are most folks will average a LOWER engine RPM due to the huge increase in low-end torque.

Given all these facts, a CF driveshaft will make almost no difference. Your money is better spend on lighter wheels/tires or lights.

Sent from my iPhone using Tapatalk

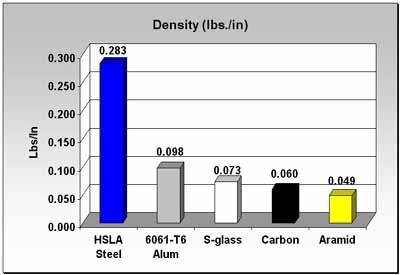

Because the driveshaft is a rotating mass, a lighter driveshaft results in less rotating mass (much like your choice to go with wheel/tire combos are are lighter - this all allows for slightly greater acceleration.

Secondly, aluminum does a better job at vibration dampening, thus allowing for a smoother ride at all speeds, but particularly so at higher speeds.

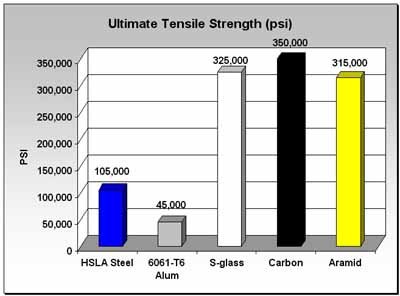

Aftermarket aluminum driveshafts can be stronger than their steel counterpart, but stiffer too, meaning more efficient transfer of power to the wheels. But if you're traversing rocks, bendability needs to be taken into consideration...

To summarize:

Less weight = less rotating mass; less rotating mass = greater acceleration

Stronger: can handle more power

Stiffer: can better transfer power

Smoother: less vibration and noise

Carbon fiber driveshafts offer all the same advantages as an aluminum driveshaft, but to an even greater extent. An aftermarket carbon fiber driveshaft is lighter, stronger and stiffer than aluminum, but also more costly!