My dealer wouldn't cover the PS pump at 36,200 miles. I actually had less than that but they told me to come back the next day when they turned me away again. I also have the extended powertrain warranty, which didn't help.

The power steering pump is actually a pretty simple job. You got the easy part done if you had 2 of the bolts and the hoses off. You really want to change this before you drive too much more since whatever crap is in the fluid is now flowing through your system including the rack. You don't want to change the rack, trust me!

Proceed as before but when you get to the hard bolts you'll want to put together a couple of extensions and a universal adapter for your socket. This will allow you to lay on your back and easily reach the bolts. If you have a friend that can blindly help hold the socket on, from the top, as you're turning it sure helps. The last 2 bolts are a pain in the ass to reach but if you use the extensions and universal you can get right on them.

I didn't remove the wheels to do mine though it may give you some extra room. You will want to put the tuck on jack stands for the flush if you can. After you get the pump swapped, you'll want to remove the reservoir and flush it out completely with some brake cleaner. You need to get as much of the residual metal shavings and crap out of the system as possible before you flush it back through the system.

Once you've cleaned everything and reinstalled all components you want to flush the entire system. The PS pump on our trucks is really strong as far as the amount of fluid it pumps. This part is definitely a 2 man job so find a friend. There are tons of opinions on how to best accomplish this so I'll just give you the easiest from my perspective.

- Truck on jack stands so both front wheels are off the ground.

- Remove the return line from the reservoir and angle towards a bucket.

- Fully fill the reservoir and turn on the key. You'll want someone stationed at the reservoir with plenty of fluid ready to pour since the pump will pull it through the system quickly.

- Turn the wheels at least 10 times fully left to right and back to left. This will take several quarts of fluid. You'll also probably need to turn the truck off several times during the process. If you hear any screeching or the guy can't keep the reservoir full, kill the engine immediately. Like I said, the pump pulls a lot of fluid very quickly. You want to make sure you're flushing all fluid from the system to include the rack.

- Kill the engine once you're getting nice clean fluid and you've turned 10 times each way.

- Reinstall the return hose, and inspect everything again

- Clean up your substantial mess since you were clumsy with the bucket and fluid is now everywhere.

- Fully service the reservoir and turn the truck back on. Turn the wheel 10 more times in each direction.

- Turn off truck and reinspect for leaks.

- Top off reservoir if it needs it now that everything was pressurized and flowing.

That method should get you moving in the right direction. The task of changing the PS pump is daily simple and straightforward but scary if you haven't done it before. If nothing else, be glad you aren't doing it on the trail somewhere. If you've got any questions as you go feel free to hit me up. I'm mostly bored today.

Pro-tip: Don't hold the wheel so hard in the future. If you are white knuckling the steering wheel, you'll cause the pressure spikes that kill your pump.

Step 1. Remove air filter and intake, Skid plate, and serpentine belt....

Step 2. Drain out PS fluid

step 3. remove oil filter and oil run off pan

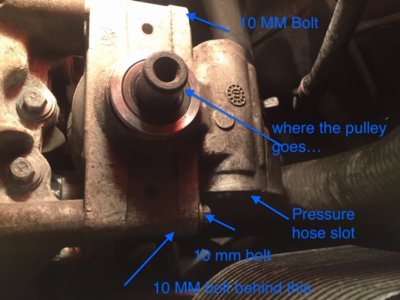

step 4. remove pulley from PS pump ( rent from Autozone for 40 bucks)

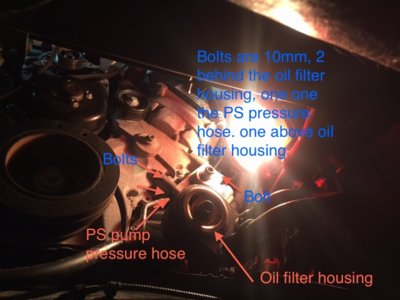

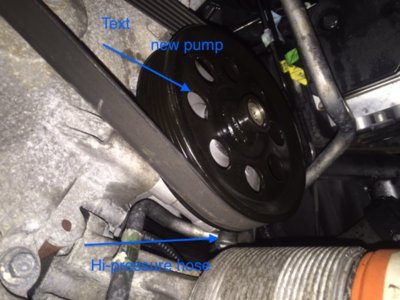

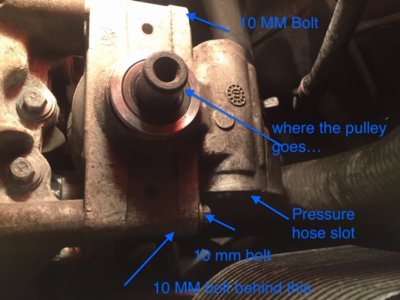

step 5. proceed to remove 10mm bolt connected to Hi-preesure hose that feeds the pump..

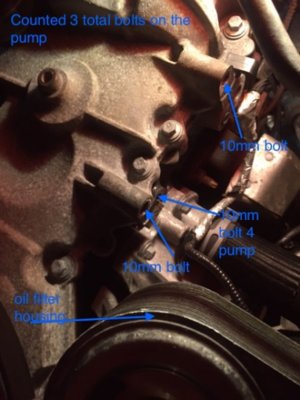

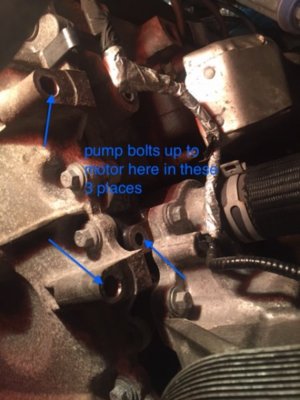

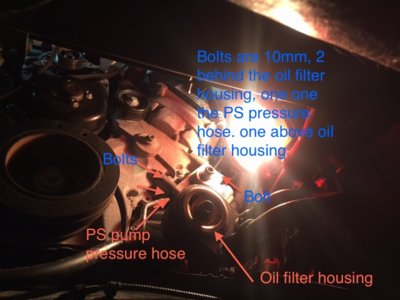

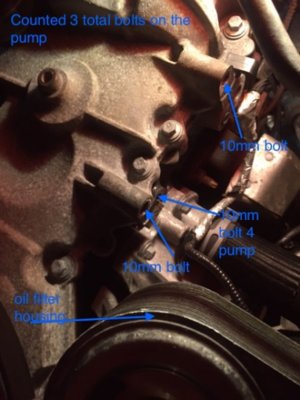

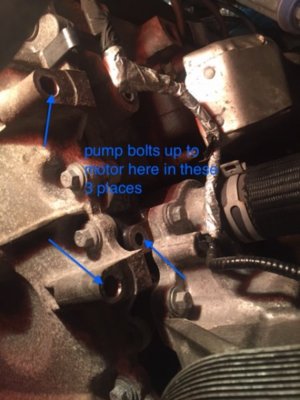

step 6. remove 10mm bolts on PS pump it should be 3 total. For the bolt on the bottom behind the hi-pressure hose, you will need a couple of extensions with a universal joint for your ratchet and a friend to help guide it in, once the bolt is released should be able to screw off with fingers.

step 7. Remove old pump.

step 8. remove pulley from new pump and install new pump.

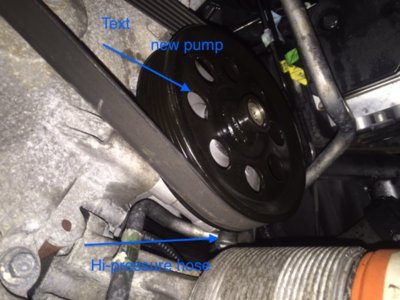

step 9. reconnect hi-pressure hose and re-install new pulley. (make sure intake and filter are reinstalled too)

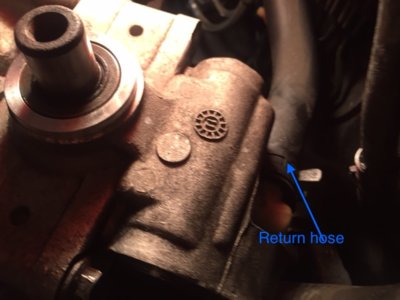

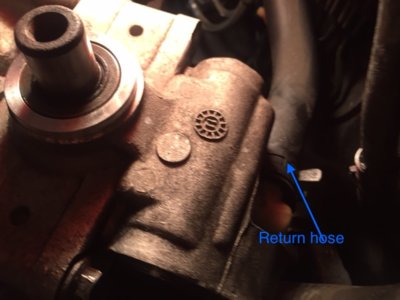

step 10. keep return hose off run it to an old cup or something to flush old fluid.

step 11. start the truck make sure everything like intake, air filter, oil filter are all connected

step 12. with truck started turn wheels from right to left with someone pouring new fluid in to keep the reservoir full till you see new fluid rushing out.

step 13. re-install return hose, make sure reservoir is full, keep the top off the reservoir to flush air out of the system. keep turning the wheels back and forth, you will hear that annoying sound the pump makes, its just getting all air out the system.

step 14. re-install skid plate and put cap back on pump.

The power steering pump is actually a pretty simple job. You got the easy part done if you had 2 of the bolts and the hoses off. You really want to change this before you drive too much more since whatever crap is in the fluid is now flowing through your system including the rack. You don't want to change the rack, trust me!

Proceed as before but when you get to the hard bolts you'll want to put together a couple of extensions and a universal adapter for your socket. This will allow you to lay on your back and easily reach the bolts. If you have a friend that can blindly help hold the socket on, from the top, as you're turning it sure helps. The last 2 bolts are a pain in the ass to reach but if you use the extensions and universal you can get right on them.

I didn't remove the wheels to do mine though it may give you some extra room. You will want to put the tuck on jack stands for the flush if you can. After you get the pump swapped, you'll want to remove the reservoir and flush it out completely with some brake cleaner. You need to get as much of the residual metal shavings and crap out of the system as possible before you flush it back through the system.

Once you've cleaned everything and reinstalled all components you want to flush the entire system. The PS pump on our trucks is really strong as far as the amount of fluid it pumps. This part is definitely a 2 man job so find a friend. There are tons of opinions on how to best accomplish this so I'll just give you the easiest from my perspective.

- Truck on jack stands so both front wheels are off the ground.

- Remove the return line from the reservoir and angle towards a bucket.

- Fully fill the reservoir and turn on the key. You'll want someone stationed at the reservoir with plenty of fluid ready to pour since the pump will pull it through the system quickly.

- Turn the wheels at least 10 times fully left to right and back to left. This will take several quarts of fluid. You'll also probably need to turn the truck off several times during the process. If you hear any screeching or the guy can't keep the reservoir full, kill the engine immediately. Like I said, the pump pulls a lot of fluid very quickly. You want to make sure you're flushing all fluid from the system to include the rack.

- Kill the engine once you're getting nice clean fluid and you've turned 10 times each way.

- Reinstall the return hose, and inspect everything again

- Clean up your substantial mess since you were clumsy with the bucket and fluid is now everywhere.

- Fully service the reservoir and turn the truck back on. Turn the wheel 10 more times in each direction.

- Turn off truck and reinspect for leaks.

- Top off reservoir if it needs it now that everything was pressurized and flowing.

That method should get you moving in the right direction. The task of changing the PS pump is daily simple and straightforward but scary if you haven't done it before. If nothing else, be glad you aren't doing it on the trail somewhere. If you've got any questions as you go feel free to hit me up. I'm mostly bored today.

Pro-tip: Don't hold the wheel so hard in the future. If you are white knuckling the steering wheel, you'll cause the pressure spikes that kill your pump.

Step 1. Remove air filter and intake, Skid plate, and serpentine belt....

Step 2. Drain out PS fluid

step 3. remove oil filter and oil run off pan

step 4. remove pulley from PS pump ( rent from Autozone for 40 bucks)

step 5. proceed to remove 10mm bolt connected to Hi-preesure hose that feeds the pump..

step 6. remove 10mm bolts on PS pump it should be 3 total. For the bolt on the bottom behind the hi-pressure hose, you will need a couple of extensions with a universal joint for your ratchet and a friend to help guide it in, once the bolt is released should be able to screw off with fingers.

step 7. Remove old pump.

step 8. remove pulley from new pump and install new pump.

step 9. reconnect hi-pressure hose and re-install new pulley. (make sure intake and filter are reinstalled too)

step 10. keep return hose off run it to an old cup or something to flush old fluid.

step 11. start the truck make sure everything like intake, air filter, oil filter are all connected

step 12. with truck started turn wheels from right to left with someone pouring new fluid in to keep the reservoir full till you see new fluid rushing out.

step 13. re-install return hose, make sure reservoir is full, keep the top off the reservoir to flush air out of the system. keep turning the wheels back and forth, you will hear that annoying sound the pump makes, its just getting all air out the system.

step 14. re-install skid plate and put cap back on pump.